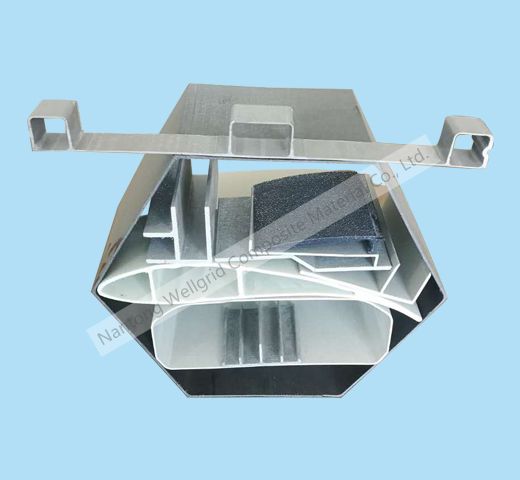

Iphrofayili ye-FRP Pultruded

I-WELLGRID inguzakwethu wakho wobunjiniyela we-FRP handrail, guardrail, iladi kanye nezidingo zomkhiqizo wesakhiwo. Ithimba lethu lobunjiniyela obuchwepheshile nokubhala lingakusiza ukuthi uthole isisombululo esifanele esihlangabezana nezidingo zakho zokuphila isikhathi eside, ukuphepha kanye nezindleko.

Izici

Ukukhanya kwesisindo

Iphawundi ngephawundi, Izimo zethu zesakhiwo se-fiberglass pultruded zinamandla kunensimbi ohlangothini lobude. I-FRP yethu inesisindo esingafika ku-75% ngaphansi kwensimbi futhi ngo-30% ingaphansi kwe-aluminium - ikahle uma kubalwa isisindo nokusebenza.

Ukufaka Easy

I-FRP ibiza ngokwesilinganiso ngaphansi kuka-20% ngaphansi kwensimbi ukuze ifakwe ngesikhathi esincane sokunciphisa, okokusebenza okuncane, kanye nomsebenzi ongakhethekile. Gwema abasebenzi abakhethekile ababizayo kanye nemishini esindayo, futhi usheshise inqubo yokwakha ngokusebenzisa imikhiqizo yesakhiwo ephukile.

I-Chemical Corrosion

Izinhlanganisela ze-fiber reinforced polymer (FRP) zinikeza ukumelana nohlu olubanzi lwamakhemikhali kanye nezindawo ezinokhahlo. Sinikeza umhlahlandlela ogcwele wokumelana nokugqwala ukuze uqinisekise ukusebenza kwemikhiqizo yayo kwezinye izimo ezinzima kakhulu.

Isondlo Mahhala

I-FRP iqinile futhi imelana nomthelela. Ngeke ibole noma igxumeke njengezinsimbi. Imelana nokubola nokugqwala, iqeda isidingo sokunakekelwa njalo. Le nhlanganisela yokusebenza nokuqina inikeza ikhambi elifanele ezinhlelweni eziningi zokusebenza.

Impilo ende Yesevisi

Imikhiqizo yethu ihlinzeka ngokuqina okuvelele kanye nokumelana nokugqwala ezinhlelweni ezifunwa kakhulu, ihlinzeka impilo yomkhiqizo ethuthukisiwe ngaphezu kwezinto ezivamile. Ukuphila isikhathi eside kwemikhiqizo ye-FRP kunikeza ukonga izindleko phakathi nomjikelezo wokuphila womkhiqizo. Izindleko ezifakiwe zincane ngenxa yokulula kokufaka. Izindleko zokunakekela ziyancipha ngenxa yokuthi isikhathi sokuphumula sincane ezindaweni ezidinga ukulungiswa, futhi izindleko zokususa, ukulahla, nokufaka esikhundleni segridi yensimbi egqwalile ziyaphela.

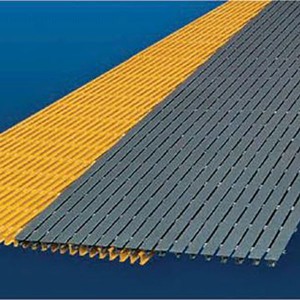

Amandla Aphakeme

I-FRP inenani eliphezulu lamandla nesisindo uma iqhathaniswa nezinto ezivamile njengensimbi, ukhonkolo nokhuni. I-FRP gratings ingaklanywa ukuthi iqine ngokwanele ukuthwala imithwalo yezimoto kuyilapho isengaphansi kwengxenye yesisindo se-steel grating.

Ukumelana Nomthelela

I-FRP ingamelana nemithelela emikhulu ngomonakalo onganakwa. Sinikeza ama-gratings ahlala isikhathi eside ukuze sanelise ngisho nezidingo zomthelela eziqinile.

Isebenza ngogesi & ne-Thermally Non-conductive

I-FRP ayisebenzisi ngogesi okuholela ekukhuleni kokuphepha uma kuqhathaniswa nezinto ezisetshenziswayo (okungukuthi, insimbi). I-FRP iphinde ibe ne-thermal conductivity ephansi (ukudluliselwa kokushisa kwenzeka ngenani eliphansi), okuholela endaweni yomkhiqizo enethezekile lapho ukuthintana ngokomzimba kwenzeka.

I-Fire Retardant

Imikhiqizo ye-FRP yakhelwe ukuthi ibe nokusabalala kwelangabi okungama-25 noma ngaphansi njengoba ihlolwe ngokuhambisana ne-ASTM E-84. Futhi bahlangabezana nezidingo zokuzicisha ze-ASTM D-635.

I-Slip Resistant

Ama-gratings ethu abunjiwe nagudlukile kanye nemikhiqizo yezitezi inikeza unyawo oluphakeme, olungasheleli endaweni emanzi nenamafutha. Insimbi iyashelela uma inamafutha noma imanzi, kodwa amagreyidi ethu anefekthri ephakeme yokukhuhlana futhi ahlala ephephile ngisho noma emanzi.

Imikhiqizo yethu imelana neziliphu yandisa ukuphepha kubasebenzi okuzoholela ezingozini ezimbalwa zasemsebenzini kanye nokwehliswa kwezindleko ezihambisana nokulimala.

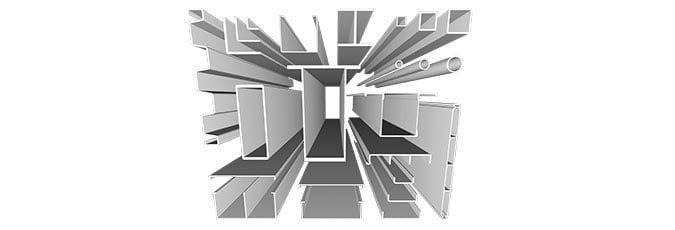

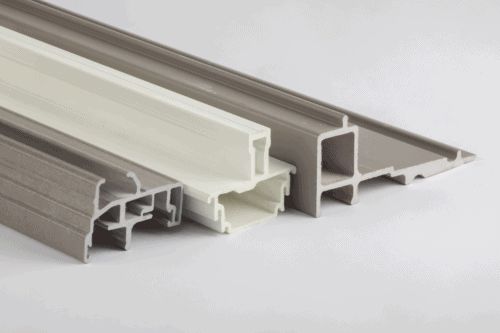

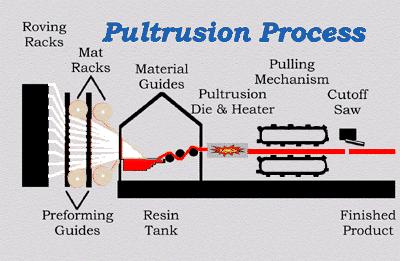

Imininingwane

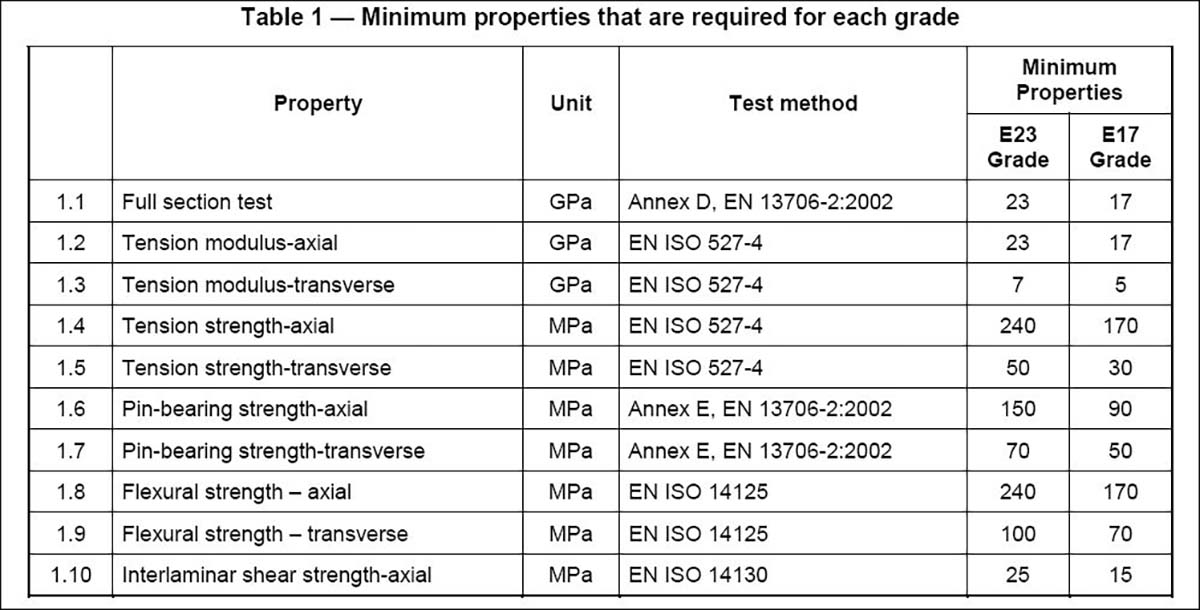

Amaphrofayili ethu esakhiwo se-pultrusion anamandla aphezulu kanye ne-modulus ngobude (LW) kanye ne-crosswise (CW) futhi ahlangabezana nezindinganiso ezifanele zase-Europe ne-America; asetshenziswa kabanzi emazweni angaphandle e-cooling tower, izimboni zamandla. Sicela usithinte ukuze uthole imininingwane yamaphrofayili esakhiwo se-pultrusion.

Sinikezela ngamaphrofayili esakhiwo se-FRP pultrusion ahlangabezana ne-EN 13706 ejwayelekile enezakhiwo ezingezansi.

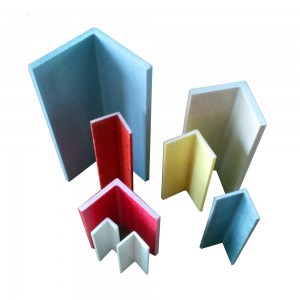

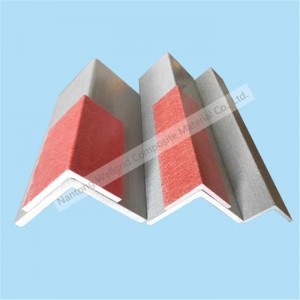

| I-engeli | H (mm) | B(mm) | T1(mm) | T2(mm) | (mm²) | (g/m) |

| 25 | 25 | 3.2 | 3.2 | 153 | 290 | |

| 30 | 20 | 4 | 4 | 184 | 350 | |

| 30 | 30 | 3 | 3 | 171 | 325 | |

| 40 | 22 | 4 | 4 | 232 | 440 | |

| 40 | 40 | 4 | 4 | 304 | 578 | |

| 40 | 40 | 8 | 8 | 574 | 1090 | |

| 50 | 50 | 5 | 5 | 475 | 902 | |

| 50 | 50 | 6.4 | 6.4 | 604 | 1147 | |

| 76 | 76 | 6.4 | 6.4 | 940 | 1786 | |

| 76 | 76 | 9.5 | 9.5 | 1367 | 2597 | |

| 101 | 101 | 6.4 | 6.4 | 1253 | 2380 | |

| 101 | 101 | 9.5 | 9.5 | 1850 | 3515 | |

| 101 | 101 | 12.7 | 12.7 | 2425 | 4607 | |

| 152 | 152 | 9.5 | 9.5 | 2815 | 5348 | |

| 152 | 152 | 12.7 | 12.7 | 3730 | 7087 | |

| 220 | 72 | 8 | 8 | 2274 | 4320 |

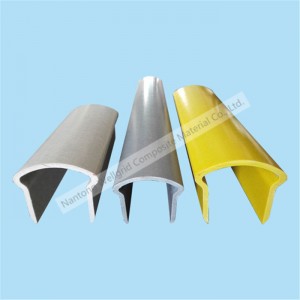

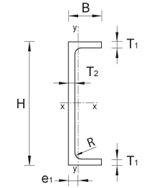

| Isiteshi | H (mm) | B (mm) | T1 (mm) | T2 (mm) | (mm²) | (g/m) |

|

| 40 | 20 | 4 | 4 | 289 | 550 |

| 50 | 14 | 3 | 3 | 220 | 418 | |

| 75 | 25 | 5 | 5 | 576 | 1094 | |

| 76 | 38 | 6.4 | 6.4 | 901 | 1712 | |

| 80 | 30 | 3.1 | 3.1 | 405 | 770 | |

| 101 | 35 | 3.2 | 3.2 | 529 | 1006 | |

| 101 | 48 | 3.2 | 3.2 | 613 | 1165 | |

| 101 | 30 | 6.4 | 6.4 | 937 | 1780 | |

| 101 | 44 | 6.4 | 6.4 | 1116 | 2120 | |

| 150 | 50 | 6 | 6 | 1426 | 2710 | |

| 152 | 35 | 4.8 | 4.8 | 1019 | 1937 | |

| 152 | 48 | 4.8 | 4.8 | 1142 | 2170 | |

| 152 | 42 | 6.4 | 6.4 | 1368 | 2600 | |

| 152 | 45 | 8 | 8 | 1835 | 3486 | |

| 152 | 42 | 9.5 | 9.5 | 2077 | 3946 | |

| 178 | 60 | 6.4 | 6.4 | 1841 | 3498 | |

| 203 | 55 | 6.4 | 6.4 | 1911 | 3630 | |

| 203 | 55 | 9.5 | 9.5 | 2836 | 5388 | |

| 254 | 72 | 12.7 | 12.7 | 4794 | 9108 |

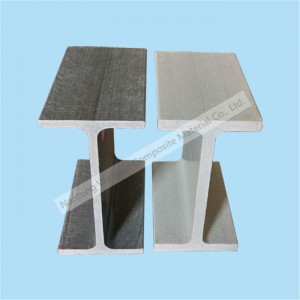

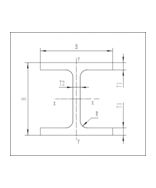

| I Beam | H(mm) | B(mm) | T1(mm) | T2(mm) | (mm²) | (g/m) |

| 25 | 15 | 4 | 4 | 201 | 381 |

| 38 | 15 | 4 | 4 | 253 | 480 | |

| 50 | 15 | 4 | 4 | 301 | 571 | |

| 76 | 38 | 6.4 | 6.4 | 921 | 1749 | |

| 102 | 51 | 6.4 | 6.4 | 1263 | 2400 | |

| 152 | 76 | 6.4 | 6.4 | 1889 | 3590 | |

| 152 | 76 | 9.5 | 9.5 | 2800 | 5320 | |

| 203 | 101 | 9.5 | 9.5 | 3821 | 7260 | |

| 203 | 101 | 12.7 | 12.7 | 5079 | 9650 | |

| 254 | 127 | 9.5 | 9.5 | 4737 | 9000 | |

| 254 | 127 | 12.7 | 12.7 | 6289 | 11950 | |

| 305 | 152 | 9.5 | 9.5 | 5653 | 10740 | |

| 305 | 152 | 12.7 | 12.7 | 7526 | 14300 |

| I-WFB Beam | H(mm) | B(mm) | T1(mm) | T2(mm) | (mm²) | (g/m) |

| 76 | 76 | 6.4 | 6.4 | 1411 | 2680 |

| 102 | 102 | 6.4 | 6.4 | 1907 | 3623 | |

| 100 | 100 | 8 | 8 | 2342 | 4450 | |

| 152 | 152 | 6.4 | 6.4 | 2867 | 5447 | |

| 152 | 152 | 9.5 | 9.5 | 4250 | 8075 | |

| 203 | 203 | 9.5 | 9.5 | 5709 | 10847 | |

| 203 | 203 | 12.7 | 12.7 | 7558 | 14360 | |

| 254 | 254 | 9.5 | 9.5 | 7176 | 13634 | |

| 254 | 254 | 12.7 | 12.7 | 9501 | 18051 | |

| 305 | 305 | 9.5 | 9.5 | 8684 | 16500 | |

| 305 | 305 | 12.7 | 12.7 | 11316 | 21500 |

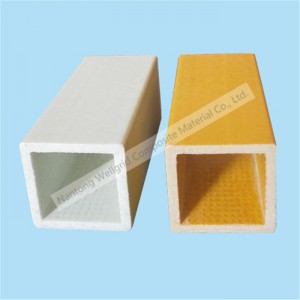

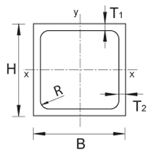

| Ishubhu yesikwele | H (mm) | B (mm) | T1 (mm) | T2 (mm) | (mm²) | (g/m) |

| 15 | 15 | 2.5 | 2.5 | 125 | 237 | |

| 25.4 | 25.4 | 3.2 | 3.2 | 282 | 535 | |

| 30 | 30 | 5 | 5 | 500 | 950 | |

| 38 | 38 | 3.2 | 3.2 | 463 | 880 | |

| 38 | 38 | 6.4 | 6.4 | 811 | 1540 | |

| 40 | 40 | 4 | 4 | 608 | 1155 | |

| 40 | 40 | 6 | 6 | 816 | 1550 | |

| 44 | 44 | 3.2 | 3.2 | 521 | 990 | |

| 44 | 44 | 6.4 | 6.4 | 963 | 1830 | |

| 45 | 45 | 4 | 4 | 655 | 1245 | |

| 50 | 25 | 4 | 4 | 537 | 1020 | |

| 50 | 50 | 4 | 4 | 750 | 1425 | |

| 50 | 50 | 5 | 5 | 914 | 1736 | |

| 50 | 50 | 6.4 | 6.4 | 1130 | 2147 | |

| 54 | 54 | 5 | 5 | 979 | 1860 | |

| 60 | 60 | 5 | 5 | 1100 | 2090 | |

| 76 | 38 | 4 | 4 | 842 | 1600 | |

| 76 | 76 | 6.4 | 6.4 | 1795 | 3410 | |

| 76 | 76 | 9.5 | 9.5 | 2532 | 4810 | |

| 101 | 51 | 6.4 | 6.4 | 1779 | 3380 | |

| 101 | 76 | 6.4 | 6.4 | 2142 | 4070 | |

| 101 | 101 | 6.4 | 6.4 | 2421 | 4600 | |

| 101 | 101 | 8 | 8 | 2995 | 5690 | |

| 130 | 130 | 9 | 9 | 4353 | 8270 | |

| 150 | 150 | 5 | 5 | 2947 | 5600 | |

| 150 | 150 | 10 | 10 | 5674 | 10780 | |

| I-tube eyindilinga | D1 (mm) | D2 (mm) | T (mm) | (mm²) | (g/m) |

|

| 19 | 14 | 2.5 | 128 | 245 |

| 24 | 19 | 2.5 | 168 | 320 | |

| 25.4 | 20.4 | 2.5 | 180 | 342 | |

| 30 | 24 | 3 | 254 | 482 | |

| 32 | 26 | 3 | 273 | 518 | |

| 40 | 32 | 4 | 452 | 858 | |

| 50 | 42 | 4 | 578 | 1098 | |

| 50 | 40 | 5 | 707 | 1343 | |

| 50 | 37.2 | 6.4 | 877 | 1666 | |

| 65 | 52.2 | 6.4 | 1178 | 2220 | |

| 76 | 63.2 | 6.4 | 1399 | 2658 | |

| 101 | 85 | 8 | 2337 | 4440 |

| Umjikelezo oqinile | D (mm) | (mm²) | (g/m) | |

| 7 | 38 | 72 | |

| 8 | 50 | 95 | ||

| 10 | 79 | 150 | ||

| 12 | 113 | 215 | ||

| 15 | 177 | 336 | ||

| 18 | 254 | 483 | ||

| 20 | 314 | 597 | ||

| 25 | 491 | 933 | ||

| 38 | 1133 | 2267 | ||

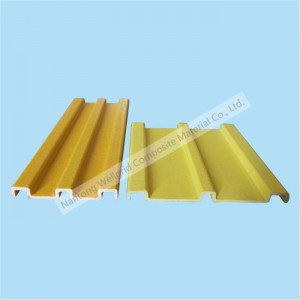

| Kick plate | B(mm) | H(mm) | T(mm) | (mm²) | (g/m) |

| 100 | 12 | 3 | 461 | 875 |

| 100 | 15 | 4 | 579 | 1100 | |

| 150 | 12 | 3 | 589 | 1120 |